Table of contents

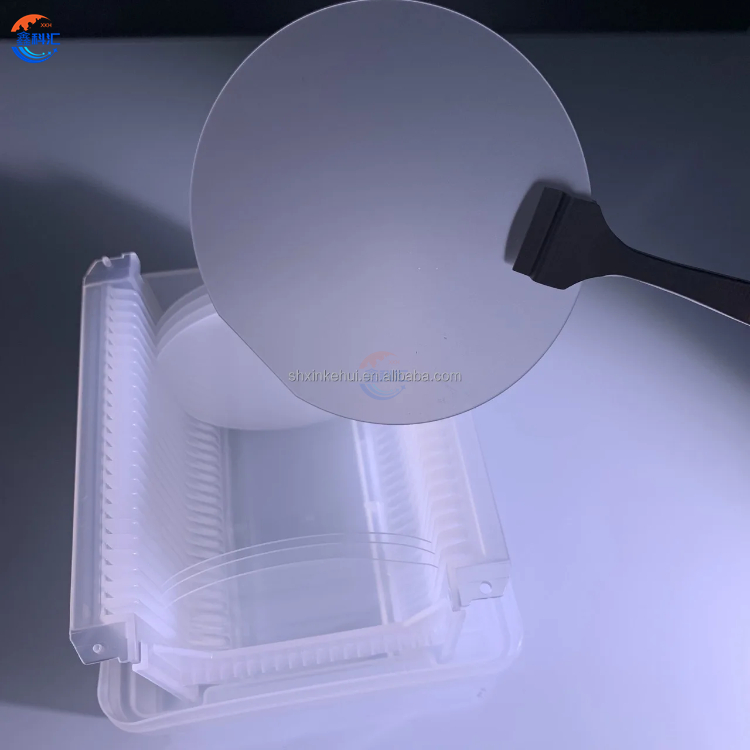

Sapphire wafer usually refers to sapphire as a substrate or substrate of the crystal disc. These wafers are commonly used in manufacturing processes in the semiconductor industry, especially for the manufacture of optoelectronic devices and optical devices.

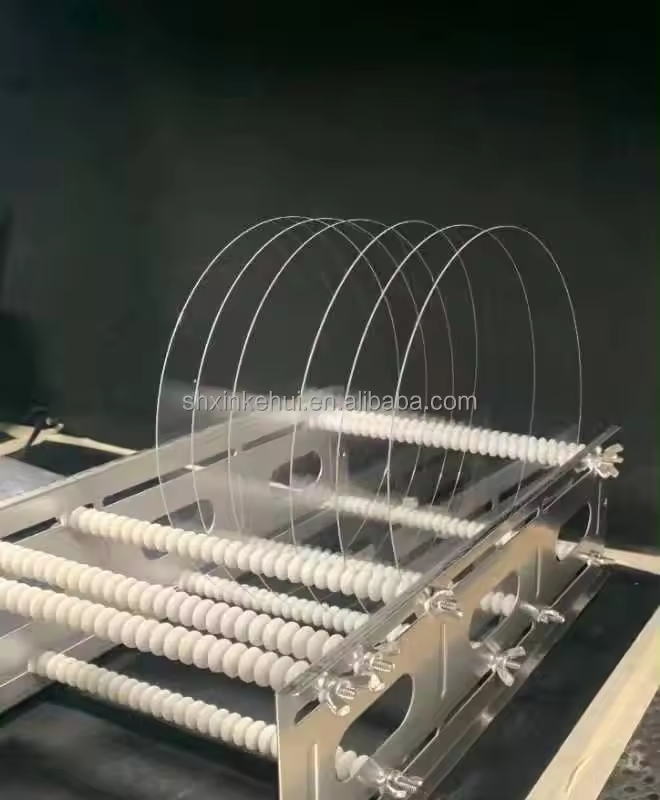

The preparation process of sapphire wafer involves processing sapphire raw material into a disk shape and subjecting it to high temperature treatment to obtain specific crystal structure and properties. Because sapphire has excellent optical and mechanical properties, it is widely used in the manufacture of high-performance optoelectronics and optical devices.

Sapphire wafers have several advantages that make them desirable for various applications:

1. Excellent Optical Properties: Sapphire wafers boasts good transparency and optical uniformity, making it an ideal material for manufacturing optical devices. Its transparency range extends widely, covering from visible light to near-infrared spectra.

2. High Thermal Stability: Sapphire wafers exhibits outstanding thermal stability and thermal conductivity, allowing it to maintain its structure and performance stability in high-temperature environments. This makes it excel in high-temperature applications, such as high-power laser output windows in lasers.

3. Hardness and Wear Resistance: Sapphire ranks second only to diamond in hardness in the natural world, thus possessing excellent wear resistance. This makes blue sapphire wafers extremely useful in applications requiring scratch resistance or durability, such as coatings for watch surfaces or optical components.

4. Chemical Stability: Sapphire wafers demonstrates good chemical stability, resisting corrosion and erosion from many chemicals. This reliability in harsh environments makes it particularly suitable for specialized applications.

5. Electrical Insulation: Sapphire wafers serves as an excellent electrical insulator, making it highly useful in applications requiring electrical isolation, such as high-voltage electronic devices.

Some common applications of sapphire wafers:

1. Laser Technology: Sapphire crystals can be used to manufacture the excitation source or output windows of lasers. They provide high thermal stability and optical transparency, making them suitable for use in various types of lasers, including solid-state lasers and semiconductor lasers.

2. Optical Devices: Sapphire wafers are utilized as substrates for optical filters, optical windows, or laser reflectors, among other optical devices. Their excellent optical properties make them ideal for applications where high optical transparency and durability are required.

3. Optoelectronic Devices: Sapphire wafers are employed in the fabrication of optoelectronic devices such as photodiodes, photodetectors, and optical communication devices. Their combination of electrical insulation, chemical stability, and optical transparency makes them valuable components in optoelectronic systems.

| Standard wafer | 2 inch C-plane sapphire wafer SSP/DSP 3 inch C-plane sapphire wafer SSP/DSP 4 inch C-plane sapphire wafer SSP/DSP 6 inch C-plane sapphire wafer SSP/DSP |

| Customized Size | 10*10mm sapphire wafer 20*20mm sapphire wafer Ultra thin (100um) sapphire wafer 8 inch sapphire wafer |

| Patterned Sapphire Substrate (PSS) | 2 inch C-plane PSS 4 inch C-plane PSS |

| 2 Inch | DSP C-AXIS 0.1mm/ 0.175mm/0.2mm/0.3mm/0.4mm/0.5mm/1.0mmt SSP C-axis 0.2/0.43mm (DSP&SSP) A-axis/M-axis/R-axis 0.43mm |

| 3 Inch | DSP/ SSP C-axis 0.43mm/0.5mm |

| 4 Inch | DSP C-axis 0.4mm/ 0.5mm/1.0mm SSP C-axis 0.5mm/0.65mm/1.0mmt |

| 6 Inch | SSP C-axis 1.0mm/1.3mmm DSP C-axis 0.65mm/ 0.8mm/1.0mmt |

e following is the general sapphire wafer size that our company(Shanghai Xinkehui New Material Co., Ltd.) can provide you with (if you have other sizes, shapes, thicknesses customized needs can feel free to contact us) :