Table of contents

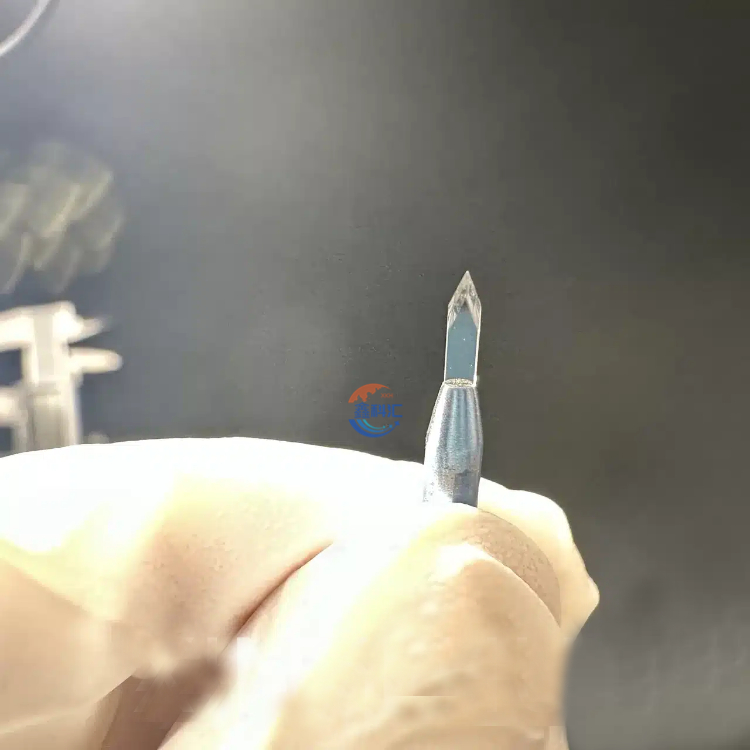

Sapphire blade is a highly specialized tool commonly used in industries and fields requiring extreme precision, durability, and resistance to wear. Sapphire, being a form of corundum, is the second hardest material after diamond, making it an ideal choice for applications that require high precision cutting, slicing, or abrasion.

Key Features of Sapphire blade:

1. Hardness: With a Mohs hardness of 9, sapphire tips and blades can withstand extreme pressures and resist wear, making them highly durable for repetitive tasks.

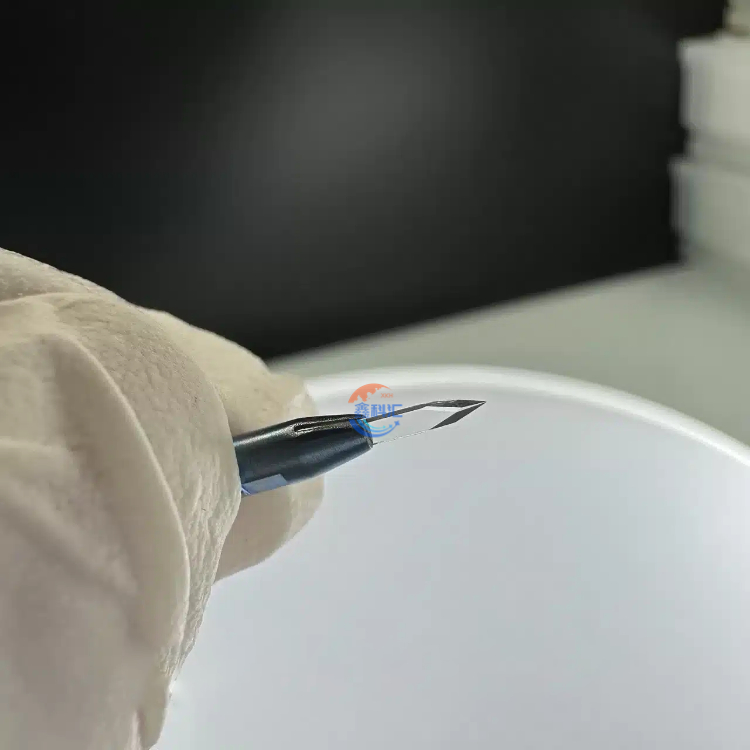

2. Precision: Sapphire blades are often honed to incredibly fine edges, allowing for precise cutting or slicing, which is crucial in industries like medical surgery, semiconductor fabrication, and scientific research.

3. Chemical Resistance: Sapphire is chemically inert, meaning it can withstand exposure to various acids, alkalis, and other harsh chemicals without degrading.

4. Thermal Stability: Sapphire maintains its structural integrity even at very high temperatures, making it suitable for environments where both mechanical strength and thermal resistance are required.

1. Parameters for sapphire blades

Here is a table of common parameters for sapphire blades, which can be adjusted according to specific application requirements:

| Parameter | Description |

| Material | Sapphire (Single-crystal Al₂O₃) |

| Hardness | 9 (Mohs scale) |

| Density | 3.98 g/cm³ |

| Melting Point | > 2000°C |

| Tensile Strength | 75-400 MPa |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and chemicals |

| Transparency Range | 150 nm – 5500 nm |

| Friction Coefficient | < 0.2 |

| Precision | Can be honed to sub-micron and nanometer-level edges |

| Biocompatibility | Non-toxic, suitable for medical and human contact |

| Thermal Expansion | 5.3 x 10⁻⁶ / °C (20-1000°C) |

| Thermal Conductivity | 25 W/m·K (at 300K) |

| Refractive Index | 1.76 – 1.77 (in visible light range) |

| Durability | High durability for frequent-use environments |

| Applications | Medical surgery, semiconductor manufacturing, precision cutting, optical instruments. |

These parameters showcase the superior performance of sapphire blades in terms of durability, precision, and resistance to extreme conditions, making them suitable for a variety of advanced applications.

2. Product Specifications

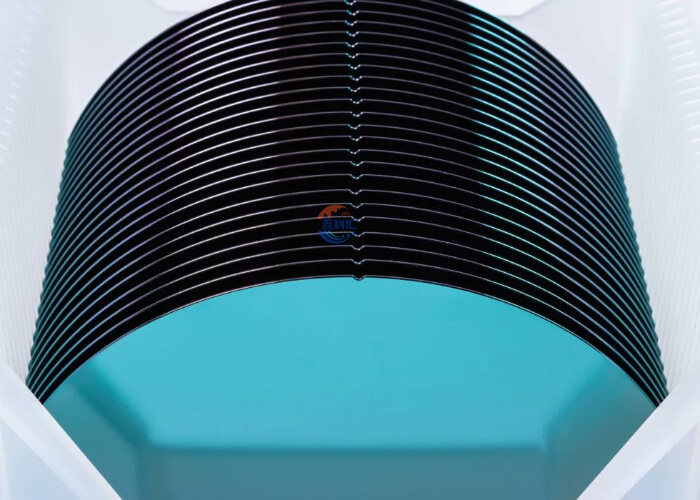

(1) Architecture: spectroscope product specifications:

(2) Basic parameters of filter:

| Serial number | Item | Actual index | Detection tool |

| 1 | Base material | Sapphire (AL2O3) | / |

| 2 | Size | Reference drawing | Quadratic element |

| 3 | Error | ±0.05mm | Quadratic element |

| 4 | Packing | Medical grade plastic packaging | / |

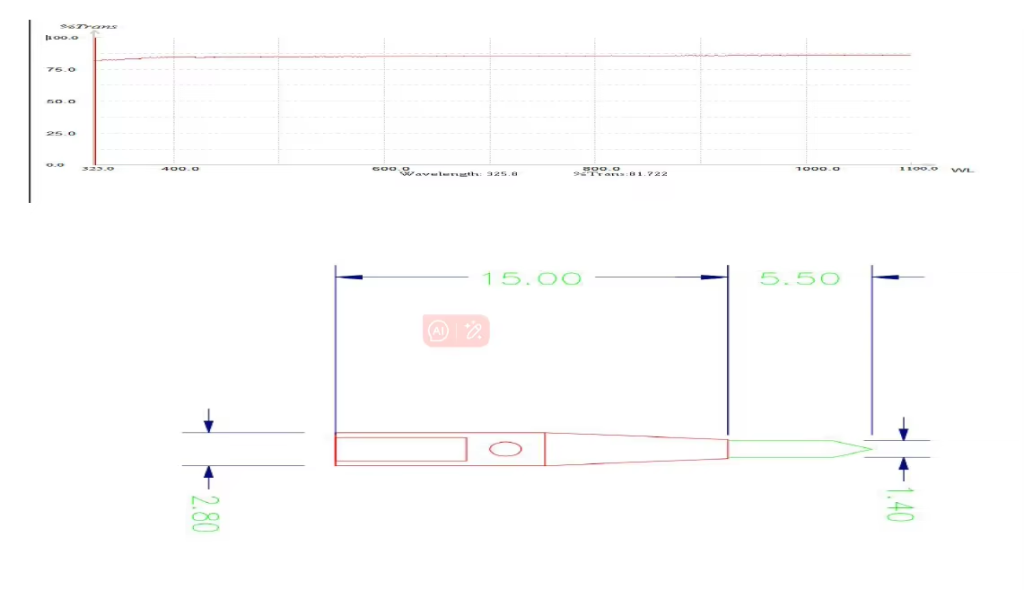

| 5 | Optical index | Incidence Angle: 0 ° 250-1100nm@T≥83% | Spectrophotometer |

| 6 | MOE hardness | 9.0 | / |

| 7 | Angle between knife point | 30°、50°、30° | Quadratic element |

| 8 | Blade Angle | 20°、60° | Quadratic element |

| 9 | Blade width | 1.0、1.2、1.4 | Quadratic element |

| 10 | Blade thickness | 0.25、0.3、0.4 | Quadratic element |

3. Product curve and appearance diagram

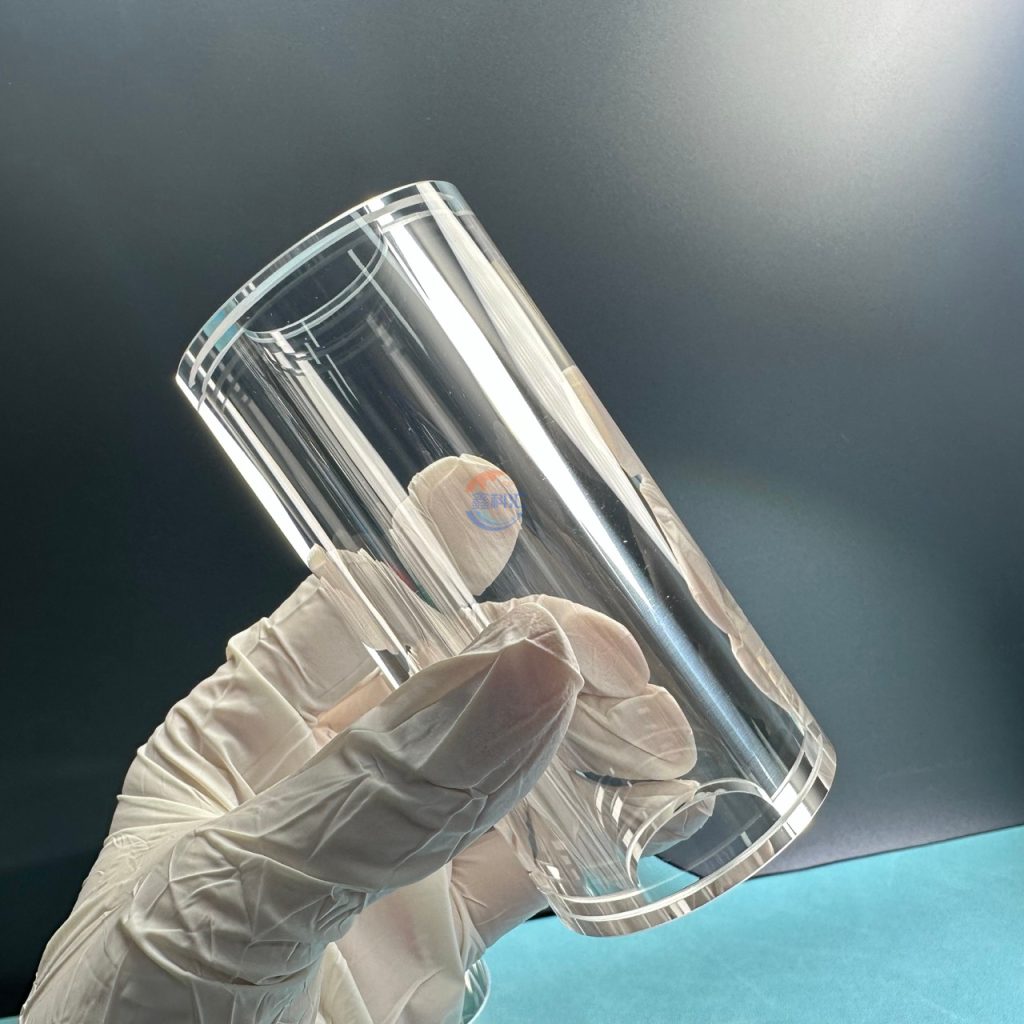

4. product appearance and environmental standards

| Surface finish | US military standard 60/40 (scratches/pitting), smooth on all four sides, no bubbles or impurities |

| Operating ambient temperature | -40℃~ +300℃ |

| Storage temperature | -40℃~ +65℃ |

| Relative humidity of the storage environment | <70% |

Sapphire blades have many unique advantages, making them widely used in various fields requiring high precision and durability. Here are their main advantages:

1. Extremely High Hardness

Sapphire has a Mohs hardness of 9, second only to diamond. Compared to metal tools and other materials, sapphire blades or tips exhibit excellent wear resistance, allowing them to maintain sharpness for extended periods in high-intensity, frequent-use environments, reducing the need for frequent tool replacements.

2. Outstanding Corrosion Resistance

Sapphire is chemically inert and can resist a variety of acids, alkalis, and other corrosive substances. This ensures that sapphire blades/tips retain their performance in harsh chemical environments without being affected by chemical reactions, making them widely used in semiconductor manufacturing and chemical industries.

3. Superior Precision

Sapphire blades can be honed to extremely sharp and precise edges, suitable for micron-level or even nanometer-level precision operations. This high precision makes them popular in fields requiring extremely accurate cutting, such as minimally invasive surgery, semiconductor manufacturing, and micromachining.

4. High-Temperature Stability

Sapphire has an extremely high melting point (over 2000°C) and maintains its mechanical strength and chemical stability at high temperatures. Therefore, it can be used in high-temperature environments for long periods without failure due to thermal expansion or chemical changes, making it ideal for high-temperature cutting and manufacturing.

5. Excellent Transparency

In addition to its hardness, sapphire offers excellent transparency, especially in ultraviolet, visible, and infrared wavelengths. Thus, sapphire tips/blades are used in optical instruments and scientific research for precise equipment that requires light transmission, such as testing and optical measurement.

6. Biocompatibility

Sapphire materials demonstrate good biocompatibility in the biomedical field, causing no rejection reactions in the human body. As a result, they are commonly used for medical surgical blades and minimally invasive surgical tools, such as sapphire blades in ophthalmic surgeries.

7. Extremely Low Friction Coefficient

Sapphire has an extremely low friction coefficient, reducing resistance during cutting, improving efficiency, and minimizing heat generation and wear.

Sapphire blades have a variety of uses, mainly including:

1. Medical surgery: used for minimally invasive surgery and ophthalmic surgery, due to its high precision and biocompatibility, reducing trauma to patients.

2. Semiconductor manufacturing: used in the semiconductor industry to cut silicon wafers and other materials, ensuring high precision and low defect rates.

3. Optical instruments: used in optical measurement and detection equipment, due to its excellent light transmittance and wear resistance.

4. Precision cutting: cutting difficult-to-handle materials such as ceramics, glass and high-hardness metals in aerospace, automotive manufacturing and electronic products.

5. Scientific research applications: in materials science and physics experiments, sapphire blades can be used for sample cutting and surface measurement.

6. Chemical analysis: used for sample segmentation and analysis in chemical laboratories, due to its corrosion resistance and suitable for a variety of chemical environments.

7. Jewelry cutting: used in high-end jewelry processing, due to its extremely high hardness, it can finely cut and polish gemstones.

These uses show the wide application and importance of sapphire blades in various high-end fields.

Here are the advantages of Shanghai Xinkehui New Materials Co., Ltd. in producing sapphire blades/tips:

1. Advanced Technology: Utilizes internationally leading manufacturing processes and equipment to ensure high precision and quality of products.

2. High-Quality Materials: Uses premium single-crystal sapphire, providing exceptional hardness and durability suitable for various demanding applications.

3. Precision Machining: Employs precision machining techniques to achieve nanometer-level cutting accuracy, meeting the needs of high-end markets.

4. Strict Quality Control: Implements a comprehensive quality management system to ensure that each product undergoes rigorous testing before leaving the factory, meeting high standards.

5. Rich Experience: Possesses years of industry experience, deeply understanding market demands and quickly responding to customer customization needs.

6. Excellent Customer Service: Offers professional technical support and after-sales service to assist customers in resolving issues during use.

7. Innovative R&D: Continuously invests in research and development to launch new products, adapting to rapidly changing market needs.

We have an experienced engineering and technical team and management experience, as well as precision processing equipment and testing instruments. We have strong non-standard product processing capabilities and can design various new product developments according to customer needs. The company will adhere to the “customer-centric, quality-based” principle and strive to build a first-class optoelectronic material high-tech enterprise.

These advantages position Shanghai Xinkehui New Materials Co., Ltd. competitively in the production of sapphire blades.

Xinkehui can provide you with Sapphire Blades in addition to a number of other optical applications.