Table of contents

Sapphire windows are indispensable in many fields due to their outstanding properties. Their exceptional hardness, wide optical transmission range, chemical inertness, thermal stability, and mechanical strength make them ideal for a variety of demanding applications. As technology advances, the use of sapphire windows is likely to expand further, highlighting their importance in modern science and industry.

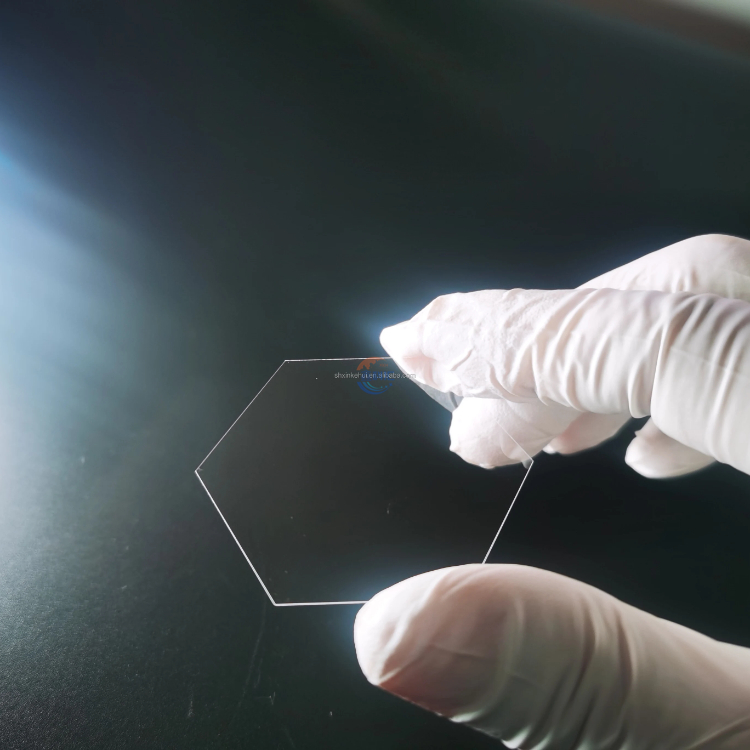

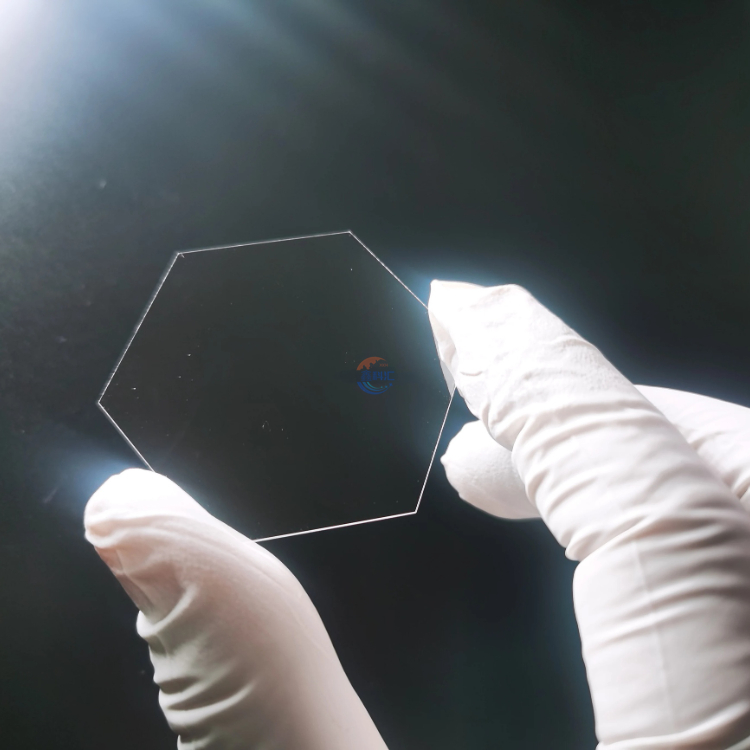

A sapphire window is a high-performance optical component made from synthetic sapphire crystal. Known for its remarkable physical and chemical properties, it is used in various demanding environments and applications.

1. Excellent hardness: Sapphire is one of the hardest materials, second only to diamond. This makes sapphire windows highly resistant to scratches and abrasions.

2. Wide optical transmission range: Sapphire windows provide high transparency over a broad spectral range from ultraviolet (UV) to infrared (IR) range (approximately 150 nm to 5500 nm). This makes them suitable for a variety of optical applications.

3. Chemically inert: Sapphire is highly resistant to chemical corrosion, which allows sapphire windows to withstand exposure to acids, alkalis, and organic solvents.

4. Thermal stability: The melting point of sapphire is approximately 2030°C, which allows the sapphire window to withstand extreme temperatures without degradation, making it ideal for high-temperature environments.

5. Mechanical strength: Sapphire windows have excellent mechanical strength and toughness, allowing them to withstand high pressure and mechanical impact.

1. Optical systems: Due to its excellent transparency and durability, it is used in high-precision optical instruments such as spectrometers, laser systems and infrared imaging devices.

2. Consumer Electronics: Used as protective screens for high-end smartphones, watches, and other portable electronic devices to enhance durability and scratch resistance.

3. Aerospace: Windows and optical sensors used in aircraft, satellites and other space vehicles in the aerospace industry to ensure reliability under extreme conditions.

4. Industrial Inspection: Used in industrial equipment to protect cameras and sensors in harsh environments including high temperatures, pressure and corrosive conditions.

5. Medical Devices: Used in medical devices such as endoscopes and microscopes where high optical clarity and durability are critical.

6. Protective Equipment: Used in applications that require both transparency and stiffness, such as ballistic glass and goggles for protective helmets.

| Material | Sapphire |

| Surface S/D | DSP 60/40 |

| Diameter Tolerance | +/-0.03 mm |

| Thickness Tolerance | +/-0.01 mm |

| Cler Aperture | Over 90% |

| Flatness | /4 @632.8nm |

| Surface Quality | 80/50~10/5 scratch and dig |

| Transmission | above 92% |

| Chamfer | 0.1-0.3 mm x 45 degree |

| Focal Length Tolerance | +/-2% |

| Back Focal Length Tolerance | +/-2% |

| Coating | Available |

| Usage | Opticl system, photographic sysem, Lighting system,Electronic apparatuse.g.laser,camera,monitor,projector,magnifier,telescope,polarizer,electronic instrument,led etc. |

Shanghai Xinkehui New Materials Co., Ltd. was founded in 2020. Its predecessor was “Zhiming (Shanghai) Trading Co., Ltd.” established in 2014. It is a professional semiconductor material solutions provider committed to providing high-quality semiconductors to global customers. Material.

The company owns two production bases and one business center, namely the production base in Wuhan, Hubei, the production base in Wuxi, Zhejiang, and the Wanda Mao Business Reception Center in Qingpu, Shanghai. The annual production capacity reaches 1 million sapphire tubes. With excellent technical capabilities and strict quality control, Sapphire Technology enjoys a high reputation in the industry.

Xinkehui may have the following advantages in the production of sapphire Windows:

1. Professional technical team: The company may have experienced engineers and technicians who can handle the technical challenges in the sapphire window production process and provide high-quality products.

2. Advanced manufacturing equipment: Xinkehui may be equipped with advanced manufacturing equipment and processes that enable high-precision machining and high-quality surface treatment to ensure the performance and reliability of sapphire windows.

3. Quality control system: The company may have established a strict quality control system to strictly control everything from raw material procurement to finished product delivery to ensure stable and reliable product quality.

4. Customization capabilities: Xinkehui may be able to provide customized sapphire window products according to customers’ specific needs, including different sizes, shapes, thicknesses and surface treatments.

5. Cost-Effectiveness: Since the company may have economies of scale and production efficiency advantages, production costs may be relatively low, thus offering competitive prices to customers.

6. After-sales service: The company may provide comprehensive after-sales service, including technical support, product warranty and after-sales maintenance, to ensure customer satisfaction during use.

These advantages may make Xinkehui a reliable partner in the production of high-quality sapphire Windows, providing customers with quality products and services.

In addition to sapphire window, we can also provide you with many other optical products, looking forward to your consultation.

1. Q:What is your minimum order requirement?

A:MOQ: 10 piece

2. Q:How long will it take to execute my order ?

A:After confirming the payment.

3. Q:Can you give warranty of your products ?

A:We promise the quality, if the quality has any problems, we will produce new produces or return you money.

4. Q:How to pay?

A:T/T, Paypal, West Union, bank transfer and or Assurance payment on Alibaba and etc.

5. Q:Can you produce custom optics?

A:Yes, we can produce custom optics