Table of contents

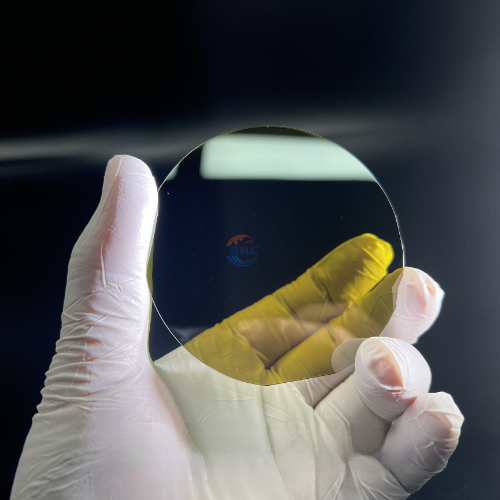

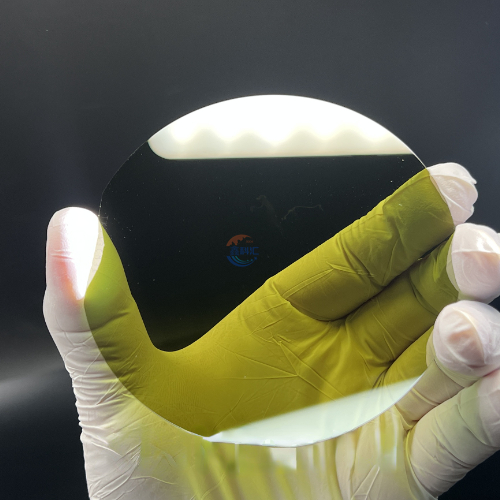

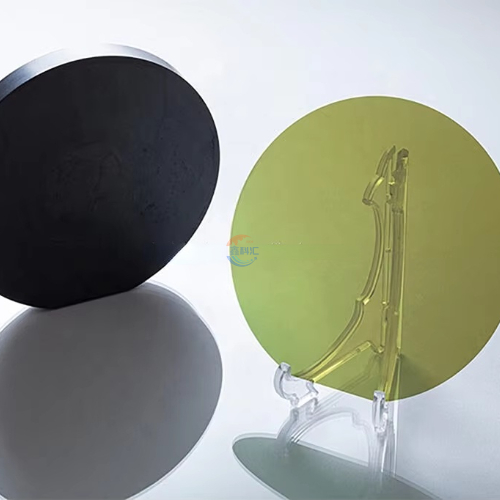

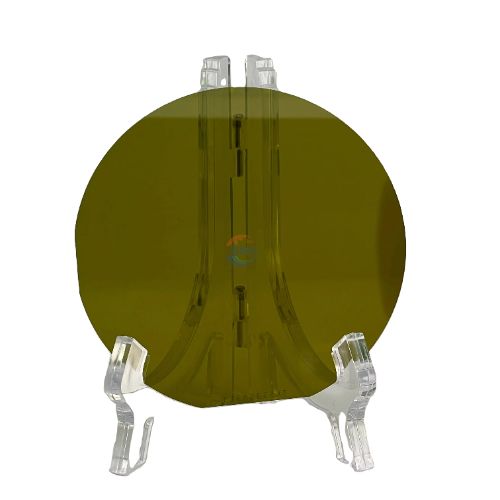

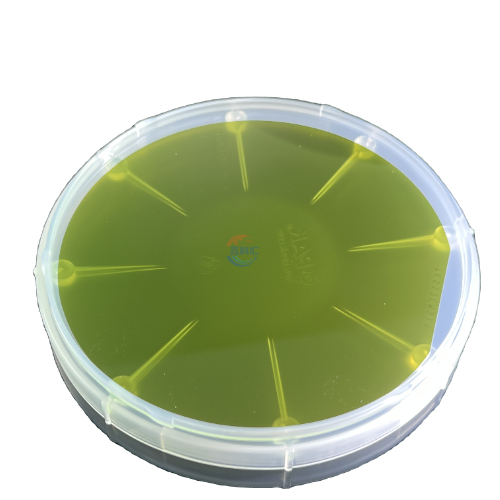

Silicon carbide wafers are a key material in the semiconductor industry, particularly valued for their superior thermal, electrical, and mechanical properties compared to traditional silicon wafers.

The production of Silicon carbide wafers primarily employs two methods: Physical Vapor Transport (PVT) and Chemical Vapor Deposition (CVD). In the PVT method, the process begins with placing a seed crystal of Silicon carbide wafers inside a high-temperature furnace. A source material, typically composed of silicon or carbon, is then heated until it vaporizes. This vapor is carried by a carrier gas, usually argon, and subsequently deposited on the seed crystal. This process results in the formation of a single crystal Silicon carbide wafers layer. Conversely, the CVD method involves depositing a Silicon carbide wafers layer on a substrate through the reaction of a gas mixture containing silicon and carbon precursors at elevated temperatures.

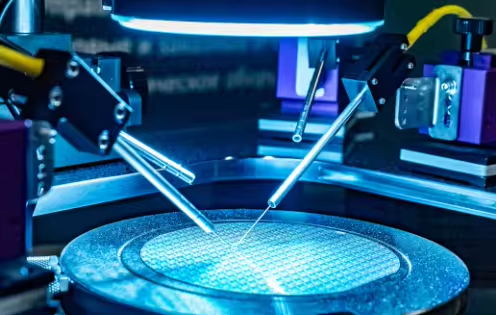

After the Silicon carbide crystal is successfully grown, it undergoes a series of meticulous steps to be sliced into thin wafers. These wafers are then polished to achieve a high degree of flatness and smoothness, essential for further semiconductor layer growth. The polished Silicon carbide wafers serve as a robust platform for the deposition of additional semiconductor layers. These layers can be precisely doped with impurities to create p-type and n-type regions, which are fundamental for the fabrication of various semiconductor devices.

Silicon carbide wafers offer several significant advantages over traditional semiconductor materials such as silicon. One of the most notable benefits silicon carbide wafers is higher thermal conductivity, which allows it to sustain operation at higher temperatures without succumbing to thermal breakdown. Additionally, silicon carbide wafers is higher breakdown voltage enables devices made from it to operate at much higher voltages and frequencies than those made from silicon. These properties render silicon carbide wafers particularly suitable for high-power electronics and high-frequency devices, where performance and reliability under extreme conditions are paramount.

In summary, the unique properties of silicon carbide wafers, including their high thermal conductivity, superior breakdown voltage, and the ability to function at high temperatures and frequencies, make them indispensable in advanced electronic and optoelectronic applications. The advanced manufacturing techniques such as PVT and CVD play a critical role in producing high-quality Silicon carbide wafers that meet the demanding requirements of modern semiconductor devices.

1. High Thermal Conductivity: Silicon Carbide Wafers has excellent thermal conductivity, which helps in efficiently dissipating heat. This property is critical for high-power and high-temperature applications.

2. Wide Bandgap: SiC’s wide bandgap (approximately 3.26 eV) allows it to operate at higher voltages, frequencies, and temperatures compared to silicon. This makes SiC ideal for power electronics and RF devices.

3. High Breakdown Electric Field: Silicon Carbide Wafers can withstand higher electric fields before breaking down, enabling devices to operate at higher voltages and power levels.

4. High Electron Mobility: This property allows for faster switching speeds, which is beneficial for high-frequency applications.

5. Chemical Stability: Silicon Carbide Wafer is chemically inert and resistant to oxidation, making it suitable for harsh environments.

1. Power Electronics: Used in devices such as Schottky diodes, MOSFETs, and power inverters, Silicon Carbide Wafers components can handle high voltages and power levels, enhancing efficiency and reducing energy loss.

2. RF and Microwave Devices: Silicon Carbide Wafers’s properties make it suitable for high-frequency applications, including radar and communication systems.

3. LEDs and Photonics: Silicon Carbide Wafers is used as a substrate material for the growth of gallium nitride (GaN) for LED production.

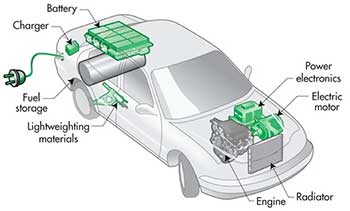

4. Automotive Industry: SiC components are increasingly used in electric vehicles (EVs) for inverters and charging systems, improving efficiency and reducing heat generation.

5. Aerospace and Defense: Silicon Carbide Wafers’s robustness and high-temperature tolerance make it ideal for applications in extreme environments, such as in satellites and military equipment.

Silicon Carbide Wafers possess several important properties, making them suitable for high-performance applications. Here are some key properties of Silicon Carbide Wafers:

Electrical Properties:

Thermal Properties:

Mechanical Properties:

Chemical Properties:

Optical Properties:

Conductivity Type:

Crystal Structure:

| Growth Method | Physical Vapor Transport | |

| Physical Properties | ||

| Structure | Hexagonal, Single Crystal | |

| Diameter | Up to 150mm, 200mm | |

| Thickness | 350µm (n-type, 3″ SI), 500µm (SI) | |

| Grades | Prime, Development, Mechanical | |

| Thermal Properties | ||

| Thermal Conductivity | 370 (W/mK) at Room Temperature | |

| Thermal Expansion Coefficient | 4.5 (10-6K-1) | |

| Specific Heat (25⁰C) | 0.71 (J g-1 K-1) | |

| Additional Key Properties of II-VI SiC Substrates (typical values*) | ||

| Parameter | N-type | Semi-insulating |

| Polytype | 4H | 4H, 6H |

| Dopant | Nitrogen | Vanadium |

| Resistivity | ~0.02 Ohm-cm | > 1∙1011 Ohm-cm |

| Orientation | 4° off-axis | On-axis |

| FWHM | < 20 arc-sec | < 25 arc-sec |

| Roughness, Ra** | < 5 Å | < 5 Å |

| Dislocation density | ~5∙103 cm-2 | < 1∙104 cm-2 |

| Micropipe density | < 0.1 cm-2 | < 0.1 cm-2 |

Silicon wafers and Silicon Carbide wafers are both fundamental materials used in the semiconductor industry, but they differ significantly in their properties, applications, and the technologies they enable. Here’s an in-depth comparison of the two:

| Material Properties | |

| Silicon Wafers | Silicon Carbide Wafers |

| Crystal Structure: Silicon has a diamond cubic crystal structure. | Crystal Structure: Silicon Carbide Wafers has a more complex crystal structure with many polytypes, the most common being 4H-SiC and 6H-SiC. |

| Bandgap: Silicon has a bandgap of about 1.1 eV, which is relatively narrow. | Bandgap: Silicon Carbide Wafers has a wider bandgap of about 2.3-3.3 eV depending on the polytype, making it a wide-bandgap semiconductor. |

| Thermal Conductivity: Silicon has a moderate thermal conductivity of about 150 W/mK. | Thermal Conductivity: Silicon Carbide Wafers has a high thermal conductivity of about 490 W/mK |

| Breakdown Voltage: Silicon has a lower breakdown voltage compared to SiC. | Breakdown Voltage: Silicon Carbide Wafers can handle much higher breakdown voltages, typically 10 times greater than silicon. |

| Electrical Properties: Silicon has good electrical conductivity, which can be modified by doping with other elements. | Electrical Properties: Silicon Carbide Wafers also has good electrical conductivity, which can be controlled through doping, but it is inherently higher resistivity than silicon. |

| Manufacturing Processes | |

| Production Method: Silicon wafers are typically produced using the Czochralski (CZ) process or the Float Zone (FZ) process. | Production Method: Silicon Carbide Wafers are produced using methods such as Physical Vapor Transport (PVT) and Chemical Vapor Deposition (CVD). |

| Raw Material: The starting material is highly pure silicon, often derived from quartz or sand. | Raw Material: The raw materials are silicon and carbon sources. |

| Process Steps: Involves melting the raw silicon, pulling a single crystal ingot, slicing the ingot into wafers, and polishing the wafers. | Process Steps: SiC crystal growth involves high-temperature processes to sublimate the raw materials and deposit them on a seed crystal, followed by slicing and polishing the grown crystal. |

| Performance Characteristics | |

| Operating Temperature: Silicon devices typically operate up to about 150°C. | Operating Temperature: Silicon Carbide Wafers devices can operate at much higher temperatures, often exceeding 300°C. |

| Switching Speed: Silicon devices have slower switching speeds compared to SiC. | Switching Speed: Silicon Carbide Wafers devices can switch faster due to their higher electron mobility. |

| Thermal Management: Silicon requires more robust cooling systems due to lower thermal conductivity. | Thermal Management: SiC’s high thermal conductivity reduces the need for extensive cooling systems. |

| Applications | |

| Consumer Electronics: Widely used in microprocessors, memory devices, and various integrated circuits found in smartphones, computers, and other consumer electronics. | High-Power Electronics: Essential for high-power, high-voltage applications such as power inverters, motor drives, and uninterruptible power supplies (UPS). |

| Photovoltaics: Silicon is the primary material used in solar cells for converting sunlight into electricity. | Automotive: Used in electric vehicle (EV) powertrains, chargers, and battery management systems due to their efficiency and ability to handle higher voltages. |

| Standard Power Electronics: Used in power diodes, transistors, and rectifiers in general power management applications. | Aerospace and Defense: Suitable for high-temperature, high-radiation environments, making them ideal for aerospace and military applications. |

| / | Renewable Energy: Employed in photovoltaic inverters and wind turbine converters for efficient energy conversion. |

| / | RF and Microwave Devices: Used in telecommunications and radar systems due to their high-frequency capabilities. |

| Cost and Market Considerations | |

| Cost: Silicon wafers are generally less expensive to produce due to well-established manufacturing processes and economies of scale. | Cost: Silicon Carbide Wafers are more expensive due to more complex manufacturing processes and lower production volumes. |

| Market Maturity: Silicon technology is mature, with extensive infrastructure and widespread adoption in various industries. | Market Maturity: The market for Silicon Carbide Wafer is growing rapidly, driven by the demand for high-efficiency, high-performance devices in automotive, renewable energy, and other sectors. |

| Challenges | |

| Temperature Limitations: Silicon’s performance degrades at high temperatures. | Manufacturing Complexity: Producing high-quality SiC bulk wafers is more challenging, involving higher temperatures and more complex processes. |

| Voltage Limitations: Silicon devices have lower breakdown voltages, limiting their use in high-power applications. | Defects: SiC crystals are more prone to defects, which can affect device performance and yield. |

| Future Prospects | |

| Continued Dominance: Silicon is expected to remain dominant in many applications, especially in consumer electronics and photovoltaics, due to its cost-effectiveness and established technology base. | Expanding Applications: Silicon Carbide Wafer is expected to see increased adoption in high-power and high-temperature applications, driven by advancements in production technology and cost reductions. |

| Innovations: Ongoing innovations in silicon technology aim to improve efficiency and performance, such as silicon-on-insulator (SOI) and advanced doping techniques. | Technological Improvements: Continued research and development are likely to reduce defects and improve the quality and affordability of Silicon Carbide Wafers. |

While both Si and Silicon Carbide wafers are critical to the semiconductor industry, they serve different roles based on their unique properties. Silicon remains the go-to material for a wide range of standard applications due to its cost-effectiveness and well-established manufacturing processes.

In contrast, Silicon Carbide wafer is increasingly favored for demanding applications where high efficiency, high temperature, and high voltage performance are essential. As technology advances, the use of SiC is expected to grow, complementing silicon in the ever-evolving landscape of semiconductor devices.

Xinkehui, as a producer of silicon carbide (SiC) wafers, offers several advantages that contribute to its competitiveness and attractiveness in the market. Here are some key advantages of Xinkehui in producing silicon carbide wafers:

Xinkehui stands out in producing silicon carbide wafers due to its commitment to advanced technology, high-quality materials, strict quality control, customization options, wide application range, and strong customer support. These advantages position Xinkehui as a reliable supplier in the semiconductor industry, meeting the demands of diverse applications that benefit from silicon carbide’s unique properties.